Search

Search

Contact

Contact

+86-0519-86483059

+86-0519-86482692

welding-factory@vip.sina.com

+86-0519-86482692

welding-factory@vip.sina.com

Product

Product Details

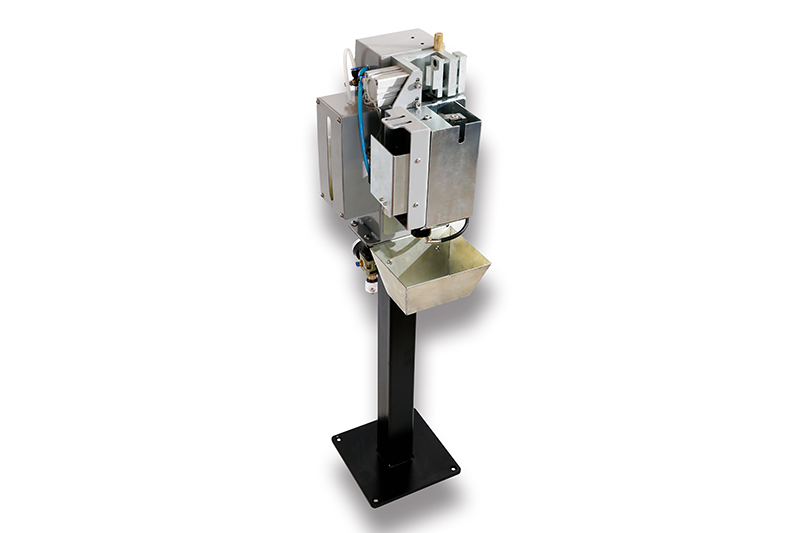

product function

1. Wire Cutting fixture

The combined clamping and shearing action guarantees precise cutting quality and ensures optimum arc start properties as well as exact TSC measurement.

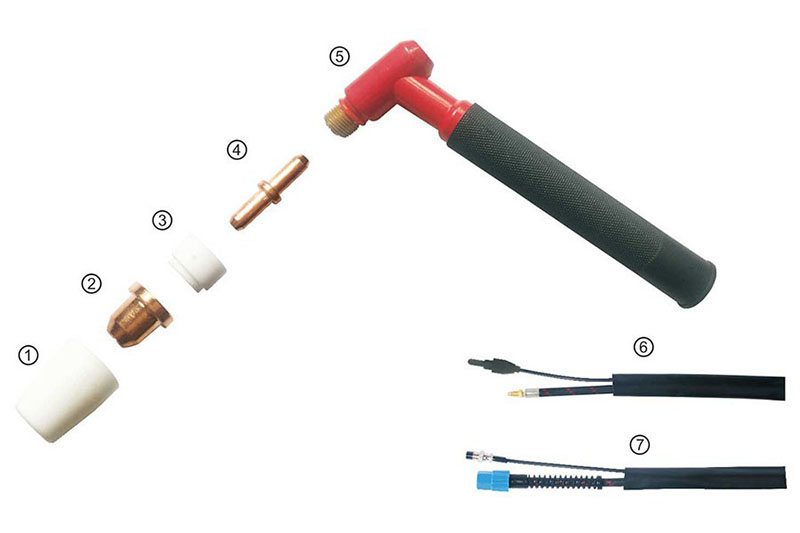

2. Torch Cleaning Station

Precise and effective cleaning for almost all robot welding torches.

Proven and trusted cutter principle, suitable even for heavy spatter adhesion.

3-point clamping of the gas nozzle fixes the torch in place during the cleaning process.

3. Spraying unit

Direct, economical spraying of all anti-spatter fluid reduces welding spatter adhesion and extends the service intervals

Clean environment thanks to encapsulated spraying nozzle and collecting pan for dirty residual oil.

Simple disposal of residual oil and replenishment of the anti-spatter agent by simply exchanging the bottles

| Product name | Robot Torch or Header Cleaning Station and Cleaner |

| Voltage | U=24V DC |

| Net weight | 14KG |

| Air Needed | 10L/S |

| Time For Cleaning | 4-5S |

| Splash proof capacity | 500ML |

| Spray-proof agent capacity | Adjustable |

1. Wire Cutting fixture

The combined clamping and shearing action guarantees precise cutting quality and ensures optimum arc start properties as well as exact TSC measurement.

2. Torch Cleaning Station

Precise and effective cleaning for almost all robot welding torches.

Proven and trusted cutter principle, suitable even for heavy spatter adhesion.

3-point clamping of the gas nozzle fixes the torch in place during the cleaning process.

3. Spraying unit

Direct, economical spraying of all anti-spatter fluid reduces welding spatter adhesion and extends the service intervals

Clean environment thanks to encapsulated spraying nozzle and collecting pan for dirty residual oil.

Simple disposal of residual oil and replenishment of the anti-spatter agent by simply exchanging the bottles

- Prev:GLA-S1 Bumper

- Next:没有了!